| QUALITY MANAGMENT |

|

When researching the origin of QUALITY( www.wikipedia.com ) it is evident that the topic has evolved rapidly from that of the ancient craftsmen’s limited guarantee of “Let the buyer be aware” to today where using statistical analysis we typically predict defects per million. As a result of increased mass production requiring consistent quality in the last 80 years, various systems or methodologies have been developed that encompass all spheres of the manufacturing value chain. This ranges from business process re-engineering to project management and the quality requirements of “the product” being manufactured. This has brought its own acronyms i.e. SPC, TQM, Six Sigma, CI, QMS, etc… Regardless of the system used there are common concepts relating

to quality. TIME AND BUDGET MANAGEMENT In 1997 E. M. Goldratt introduced Critical Chain Project Management

(CCPM) based on his Theory of Constraints (TOC) algorithms. This

places more emphasis on resources and the use of buffers. In their

analysis of 78 CCPM case studies Mabin & Balderstone found

a 69% reduction in lead time,

50% reduction in inventory levels and 68%

increase in revenue. HOW DOES AI2SA

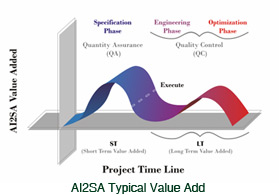

ADD VALUE BY EXPLOITING QUALITY AS THE CATALYST? Traditionally payment would be based on the completion of milestones (Design Specification, Factory Acceptance Test etc.) with no cognisance taken of the requirements specified in the Quality Control Plan (QCP). Traditionally a client would witness a test without the required test criteria and procedures been specified leaving both parties exposed to risks such as technical incorrectness, variation orders or delayed time lines. From the graph it is evident that the most value is added due

to upfront specification and these translate to short term savings

such as a possible reduction in the contracted price. The long

term value is derived by using quality to drive both progress

and performance. If there is no base line specification the project

manager has a frustrating task ahead. By focusing on the “GOLDEN

THREAD” and implementing the correct hold points

for payment risk is mitigated and results improve significantly

and client satisfaction is significantly improved. CONCLUSION We are vendor independent insuring objectivity and all our experience is based on 1st principles ensuring that best practices are adhered to. We have case studies proving how clients can save between 10% and 25% on projects using our methodologies, quality systems and templates. For more information please feel free to phone the author on +27 (0) 82 559-7437 / +27 (0) 12 993-3637 or mail him at petrus.klopper@ai2sa.co.za, feel free to visit our web site at www.ai2sa.co.za for information on the host of strategic services we offer industry.

|